- Contact us

- +7 (812) 425-24-57

Simulation-based strategic management

Global economy changes lead to thinking about new ideas and innovations that can provide companies with competitive advantages. Innovations on management level show the best efficiency, especially if we talk about management in complex systems or projects with a lot of people involved.

It is important for a manager to be supported by IT instruments that allow them to:

- Make an internal validation of taken decisions

- Get and maintain visualization that represents project state to:

- Control the process and make it transparent

- Deliver it to key company stakeholders

- Predict the results of further actions.

These goals can be achieved by establishing the simulation-based decision-making process. Simulation can help to tackle the following challenges:

- Estimation of complex problems of new technology development

- R&D department efficiency measurement

- Logistics cost reduction

- Estimation of different production and warehouse site quantity, location and configuration

- Supply chain measurement, logistics policy optimization

- Simulation-based scheduling in manufacturing

- Budgeting, P&L analysis and forecasting.

Simulation Methodology

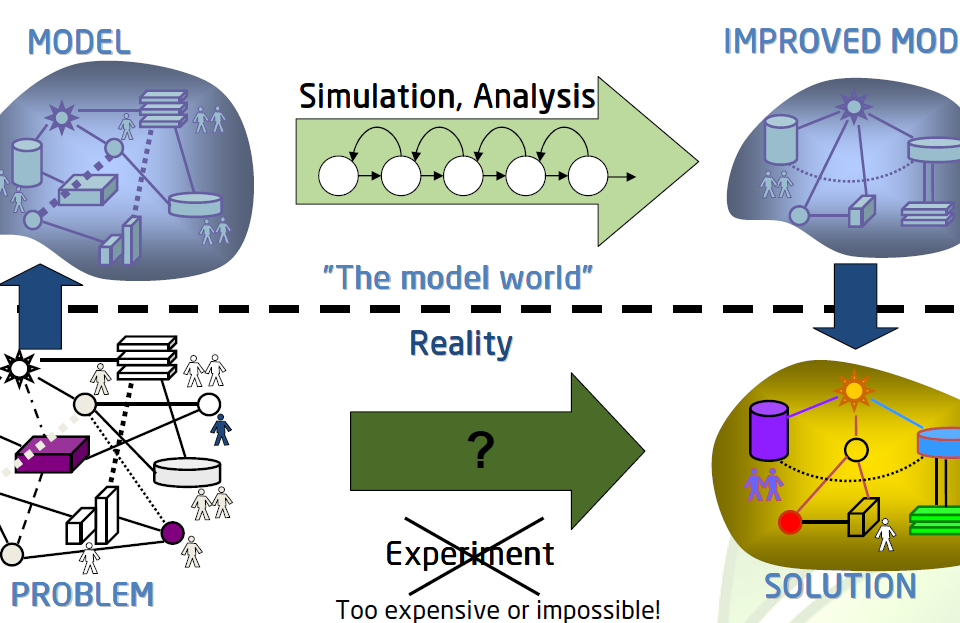

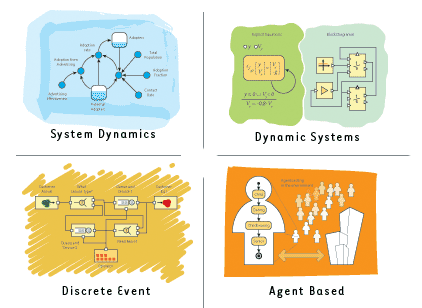

Modeling is a method of solving problems based on experiments by replacing a real object with its simplified representation, called a model.

Computer modeling is used when experimentation with a real system is impossible or inefficient because of cost of failure, or time required to get real life data.

How can simulation be applied in strategic management?

Let us assume that a country is planning to build a number of icebreakers. The first task is to estimate how many vessels are really needed. It is a typical high-level decision, how many expensive equipment units should be acquired and what parameters they should have. In our case, parameters include load-carrying capacity, seaworthiness, maximum ice depth and wind resistance. Icebreakers support other vessel types in moving in north-sea conditions. Vessel quantity and parameters strongly depend on the volume of transportation on the route that is served by the icebreakers.

Such analysis can be ordered from a sea transportation research institute, whose output will be a 300-page report which does not help in verifying the quality of the results. This is a typical black box approach. If simulation is involved, the result includes an animated model whose results are easy to verify. It seems logical to ask research organizations to provide not only a report but also a simulation model that can be understood without spending a few weeks reading reports.

The second task is where to build these vessels. There are a few shipyards in the country, let’s say it is known that two of them can be used to build this type of ships, but they both require renovation. Any strategic decision requires a choice from a set of alternatives. Usually, the choice is made by a manager and his group of advisors; based on logic, experience and intuition—it is all about mental model usage. In our case we have two choices:

- Renovate one of the shipyards so it can build all the vessels.

- Split the production. This is cheaper because the scale of renovation is lower. On the other hand, it requires transporting parts by railroad. This additional transportation affects each vessel’s building cost and time. Moreover, we can create significant additional workload on particular railroad routes that should also be analyzed.

Decisions are very likely to be inefficient when based on spreadsheet numbers and mental models. When people in a group have different opinions, the weight of these people affects results more that the system parameters.

Simulations of all alternatives can bring the decision-making from a question of trusting human intuition to a question of trusting the model. If the model is visually correct and includes all the known dependencies, it is easy to be sure of the simulation result. The model will show the future—what will be the reality in each alternative scenario—which will be easy for a group of people involved in decision-making to communicate and get a consensus on.

In addition, the model shows when the vessel will be finished, data which can be used to control operational managers. If the same processes are used in the model and in reality, but there is still a significant difference in terms; it is a good signal to check operational management effectiveness.

Moreover, the simulation model can significantly improve communication. When key specialists see how the production facility looks after modernization, they immediate find potential bottlenecks and suggest improvements. This improves communication on all levels and avoids potential mistakes.

To summarize everything above: simulation modeling can play an important role in the decision-making process.

Industry leaders already apply simulation

Simulation is frequently used by industry leaders across different verticals. This statement can be easily proven by the list of publicly available success stories:

- General dynamics: shipyard capacity analysis

- GE: simulation-based scheduling in manufacturing

- Intel: simulation model helped avoid production plant downtime

- Airbus: analysis of management strategies for aircraft production ramp-up

- GSK: supply chain design and optimization

- Pfizer: Pharmaeconomic simulation of clinical trials

- CCC: construction site simulation

- Kuehne&Nagel: warehouse operations simulation

- McDonald's: balancing supply and demand

- Port of Le Havre: internal port operation simulation.

Focus Group team has also contributed to this list by serving well-known industry giants with simulation expertise.