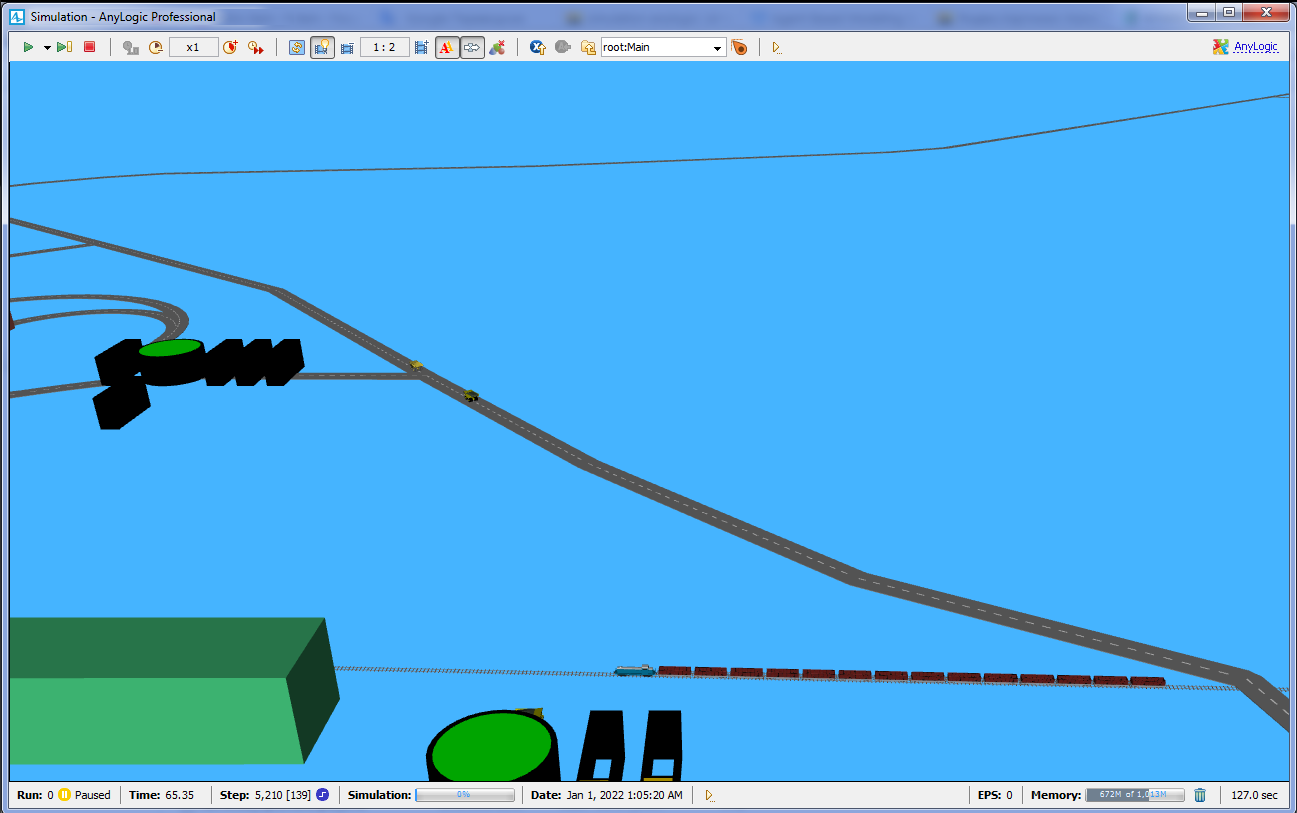

With this simulation model, you can optimize vehicle fleet mix and develop the best mine-to-processing-plant ore transportation plan. In the model, you can also reduce delivery costs and increase transportation reliability by recalculating routes in case of truck breakdowns and track blockages.

The model considers production plans, extracted raw materials, and infrastructure facilities, as well as the parameters of all equipment types. With the model, you can test if logistics structures can accommodate raw materials supply. For each structure you can calculate the flow volumes by logistics legs, as well as infrastructure requirements, and equipment and machinery costs. Based on these parameters, the optimal route is calculated.

This project was carried out for one of the world’s largest nickel producers by one of the “Big 3” strategy consultancies.

Focus Group worked as a sub-contractor for simulation modeling, initial data preparation and analysis of the modeling results. This part of the project consisted of three stages.

Model architecture development

- Choosing an optimal level of details

- Making detailed project plan for simulation model development

- Data gathering, checking and analysis

- Model scenarios creation

- Conceptual model development

Model fulfillment

- Connecting the conceptual model with company data sources

- Development of algorithms for logistics flows, equipment logic, operational constraints and events

- Model UI (user interface) development

- Model animation 2D and 3D

- Model interface setup for output reporting

- Optimization criteria definition

Model testing and usage

- Simulation experiments setup and execution

- Reporting based on the experiments

- Model verification

- Finding optimal scenario for logistic schema